Introduction: Gold as the Eternal Surface

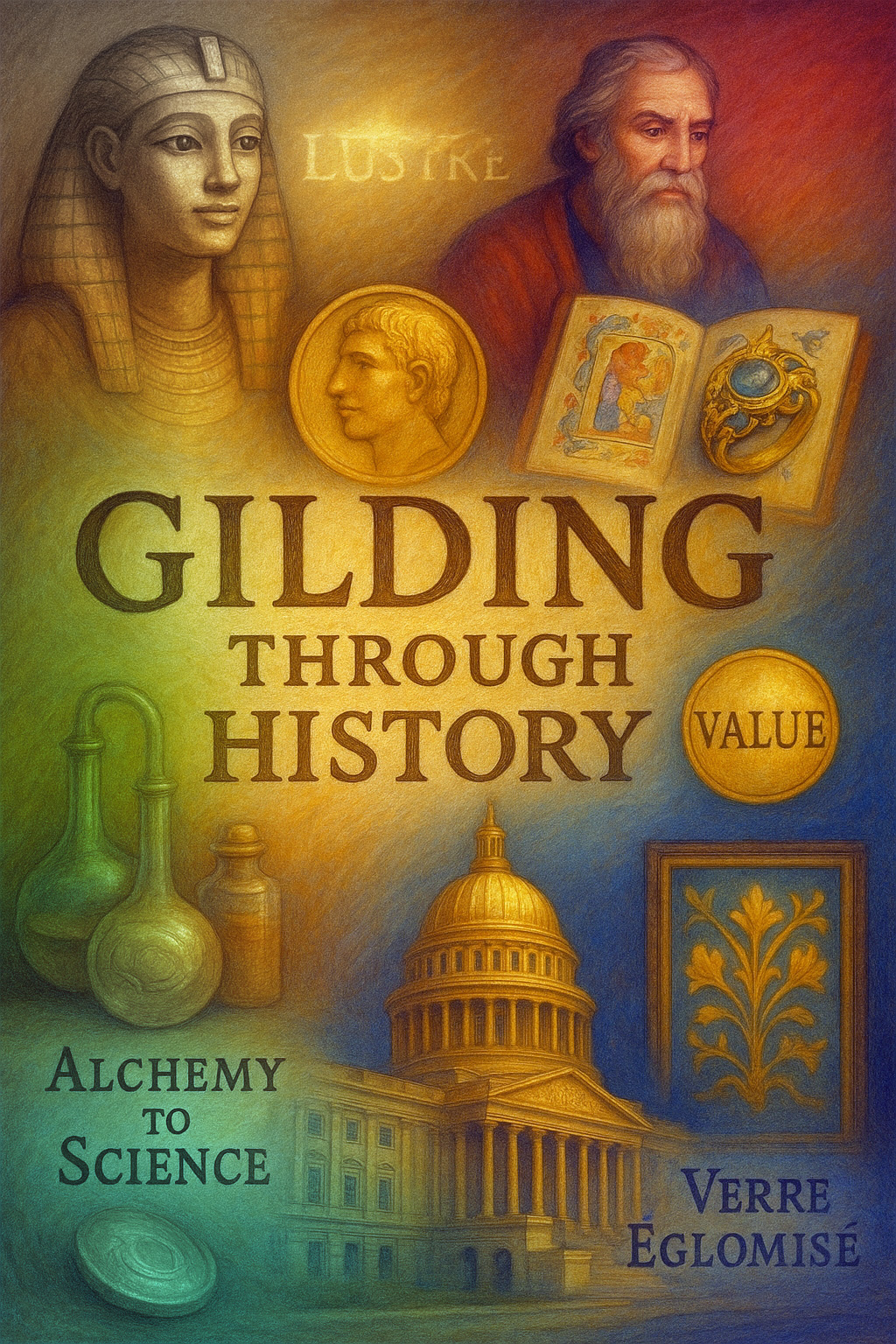

Gold has always been more than a metal — it is permanence, divinity, and wealth pressed thin and made luminous. Gilding, the art of applying gold leaf to surfaces, bridges art and industry, faith and craft, beauty and durability. From ancient temples to modern interiors, from illuminated manuscripts to architectural domes, gilding embodies humanity’s instinct to capture light.

Since 1954, SeppLeaf Products has supplied artisans, architects, restorers, and designers with the gold leaf, tools, and knowledge that sustain this tradition. As America’s leading stocking distributor of genuine gold, silver, and metal leaf in all forms, we provide the materials that make surface into statement.

Ancient Origins of Gilding

The story of gilding begins deep in antiquity:

- Egypt (3,000 BCE): Coffins, sarcophagi, and temple ornaments were layered with wafer-thin sheets of hammered gold. Egyptians believed gold represented the flesh of the gods, and by wrapping objects in leaf, they endowed them with eternal life.

- Greece & Rome: Classical temples gleamed with gold leaf highlights. Romans refined adhesives and mordants that allowed gilding on marble, stone, and wood, ensuring longevity in monumental architecture.

- Asia: In China and Japan, gilders perfected techniques of applying leaf to lacquer and wood, particularly in Buddhist temples, folding screens, and statuary. Leaf was viewed not only as ornament but as a conduit to the divine.

These early experiments set the foundation for techniques still used today.

Medieval Splendor and the Renaissance Flourish

Illuminated Manuscripts and Sacred Art

In the Middle Ages, monks applied gold leaf to religious manuscripts. Every page of a psalter or gospel was transformed into light itself, with gilded letters and miniatures shimmering in candlelit monasteries.

Altarpieces and Gothic Frames

Cathedrals and churches were wrapped in gilded detail — altarpieces, retables, shrines, and architectural tracery. Leaf was not mere ornamentation; it made the invisible divine visible.

Italian Renaissance Mastery

By the 14th and 15th centuries, Florence and Venice became gilding capitals. Italian artisans perfected water gilding, using clay bole and gesso beneath the leaf to allow high burnish. Gilded frames, panels, and furniture became both technical marvels and artistic statements.

[Link internally to “Gold Leaf Sheets” category page here]

The Industrial Age: From Workshop to Factory

Colonial America

European traditions carried into the New World, where sign makers, framers, and architects adopted gilding for domes, civic buildings, and trade signage.

19th Century Expansion

Industrial rolling mills made gold leaf more uniform and accessible. The production process could hammer leaf to extreme thinness — down to a few microns — making large-scale gilding possible.

20th Century Modernism

Art Deco and modernist architects embraced leaf as both austere and radiant. From Rockefeller Center to grand theaters, gilding became synonymous with glamour and permanence.

Gilding Techniques: Craft, Science, and Skill

Water Gilding

The oldest and most luminous technique, water gilding involves gesso and bole layers, leaf application with water, and final burnishing with an agate stone. The result: mirror-like brilliance.

Oil Gilding

Developed for durability, especially outdoors, oil gilding uses an adhesive “size” that holds leaf securely to stone, glass, or metal.

Patent vs. Loose Leaf

- Patent Leaf: Leaf pre-mounted on tissue for easier handling, popular with sign makers.

- Loose Leaf: Traditional sheets requiring skilled handling with gilder’s tips and knives.

Specialty Metal Leaf

Silver, copper, palladium, variegated, and imitation gold expand the palette. [Link internally to “Metal Leaf” category page]

Tools, Brands, and Materials that Shape the Craft

SeppLeaf Products curates and distributes tools and supplies from the world’s most respected makers:

- Manetti – Italy’s historic leaf producers, unmatched in gold and silver.

- Crocodile (Eytzinger) – German precision and consistency.

- Brambilla Best, Nazionale, Liberon, Mixol, Kolcaustico, GoldGourmet – Specialists in brushes, sealers, clays, pigments, and edible gold.

Each brand represents decades — even centuries — of expertise, carried forward into today’s projects.

[Link internally to “Gilding Tools & Supplies” category page]

Gilding Today: Art, Design, and Industry

- Fine Art: Contemporary artists use leaf conceptually, blending ancient material with modern expression.

- Interior Design: Walls, ceilings, and furniture panels glow with gold and silver accents.

- Architecture: Domes, signage, and exterior ornament use leaf for permanence.

- Food & Luxury: Edible leaf in spirits, confections, and fine dining.

From museums to hotels, gilding remains a versatile surface treatment that signals both tradition and modernity.

SeppLeaf Products: A Legacy Since 1954

Founded in New York in 1954, SeppLeaf Products became America’s trusted gilder’s source. We are not only a stocking distributor but also an educator and partner. Workshops, technical guides, and decades of expertise ensure that when artisans choose SeppLeaf, they choose reliability.

Every sheet, every roll, every tool we carry serves one purpose: to make great works in gold possible.

Conclusion: Gold, Time, and Transformation

Gilding is the art of transformation — base material into brilliance, surface into symbol, craft into legacy. The tradition stretches back five millennia, but it remains alive every time an artisan lifts a sheet of leaf.

At SeppLeaf Products, we honor that tradition by supplying the finest materials and tools. For every artist, designer, architect, or craftsman who asks: Where does great work in gold begin? — the answer is here.